1. Visual Inspection

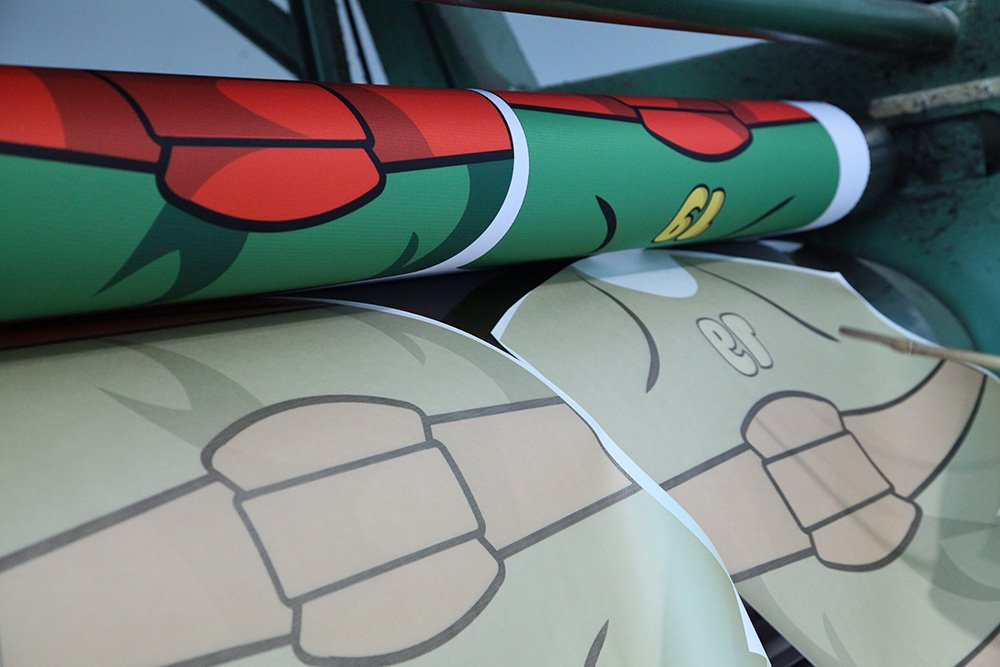

- Check for Vibrancy: The colors should be bright and match the original design. Sublimation printing is known for its ability to produce vivid and rich colors.

- Examine Details: Ensure that intricate details, text, and logos are sharp and clear. There should be no blurriness or bleeding of colors.

2. Color Consistency

- Uniformity Across Pieces: All uniforms should have consistent colors. Compare multiple pieces to ensure there are no variations in color shades.

- Pantone Matching: If specific colors were chosen based on Pantone codes, ensure the printed colors match these codes accurately.

3. Durability Tests

- Wash Test: Wash a sample uniform multiple times according to the care instructions. The print should remain intact without fading, cracking, or peeling.

- Stretch Test: Stretch the fabric to check if the print distorts or fades. High-quality sublimation prints will maintain their integrity even when the fabric is stretched.

4. Feel of the Fabric

- Smooth Surface: Run your fingers over the print. The fabric should feel smooth, with no noticeable texture change between the printed and non-printed areas.

- Breathability: Ensure the fabric retains its breathability. Sublimation printing should not affect the moisture-wicking properties of performance fabrics.

5. Print Alignment

- Positioning Accuracy: Verify that the design elements are correctly aligned as per the original layout. Logos, numbers, and other elements should be perfectly positioned.

- Symmetry: Check that the designs on both sides of the uniform (e.g., sleeves, front, and back) are symmetrical and properly aligned.

6. Colorfastness

- Sunlight Exposure: Expose the printed uniforms to sunlight for extended periods and check if the colors remain vibrant and do not fade.

- Sweat Resistance: Wear the uniforms during intense physical activity and check if sweat affects the print quality.

7. Edge and Seam Inspection

- Seam Durability: Examine the seams and edges where the print meets the stitching. The print should not crack or peel away from the seams.

- Edge Clarity: Ensure that the edges of printed areas are clean and precise, with no fraying or feathering.

8. Feedback from Wearers

- Comfort: Collect feedback from team members regarding the comfort and fit of the uniforms. The print should not cause any irritation or discomfort.

- Performance: Ensure that the uniforms maintain their performance features, such as flexibility and moisture-wicking, even after printing.

9. Consistency in Batch Production

- Sample Testing: Regularly test samples from different batches to ensure consistent quality across all production runs.

- Documentation: Keep records of quality checks and any issues identified during production to address recurring problems.

Conclusion

Verifying the quality of sublimation printing for team uniforms involves a combination of visual inspections, durability tests, and feedback from users. By following these steps, you can ensure that your team uniforms are not only visually appealing but also durable and comfortable. High-quality sublimation printing will enhance your team’s appearance and performance, making it a worthwhile investment.

有限公司_画板-1.png)